IEC 62133 Battery Drop Tester – BONAD Steel Plate Battery Drop Test Machine

Standards:

This tester complies with the following international standards:

- IEC 62133-1:2017 (Clause 7.3.3): Free fall test for batteries.

- IEC 60086-4 (Clause 6.5.4): Free fall test for primary batteries.

- IEC 60086-1: General requirements for primary batteries.

- UN 38.3 : Lithium battery transport safety standard.

These standards ensure that the equipment provides reliable and repeatable results for battery safety testing.

Application:

The IEC 62133 Battery Drop Tester is widely used in industries where battery safety and product durability are critical. Its applications include:

- Battery Manufacturers: Testing the safety and structural integrity of lithium-ion, nickel-metal hydride, and other types of batteries.

- Consumer Electronics Industry: Evaluating the durability of small electronic devices such as mobile phones, MP3 players, electronic dictionaries, and more.

- Research & Development: Conducting safety tests during the development phase of new battery technologies.

- Quality Control: Ensuring compliance with international safety standards in production environments.

Features:

This tester offers several advanced features that enhance its functionality and accuracy:

- Package Face, Corner, Edge Free Drop Testing: Supports comprehensive testing of different drop orientations for realistic simulation.

- Digital Height Display: Equipped with an encoder-based height measurement system for precise control of drop height within ±2% or ±10mm tolerance.

- PLC Touch Screen Control: User-friendly interface for easy operation and parameter setting.

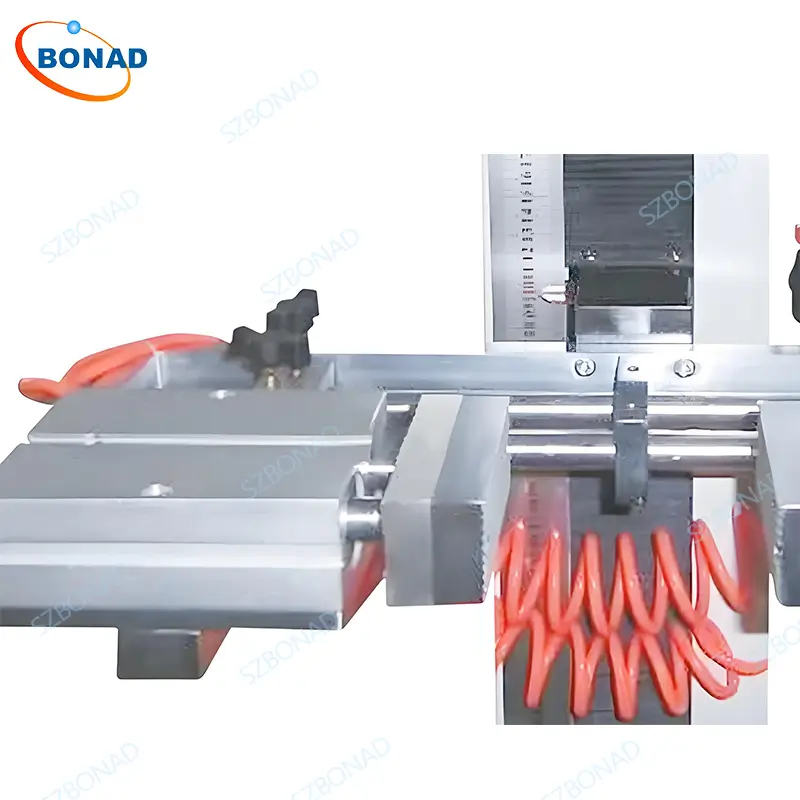

- Pneumatic Structure: Utilizes pneumatic cylinders for secure specimen fixation and controlled release during testing.

- A3 Steel Plate Impact Surface: Provides a durable and standardized impact surface for accurate results.

- Customizable Drop Floor Options: Meets various testing standards with optional impact surfaces.

- Automated Lifting System: Automatically lifts specimens to the pre-set height, reducing manual errors and improving efficiency.

Test Procedures:

- Charge the Battery: Fully charge the battery according to the first procedure (7.1.1) of IEC 62133.

- Mount the Specimen: Power up the drop test machine and securely mount the specimen in the pneumatic gripper.

- Set the Target Height: Use the touch screen to set the drop height to 1 meter.

- Initiate the Drop Test: Tap the “Drop” key to release the specimen for a free fall. Ensure the ambient temperature is maintained at (20 ± 5)°C.

- Repeat the Test: Perform the test three times for each specimen.

- Visual Inspection: After resting the specimen for at least 1 hour, visually inspect it for any signs of fire or explosion.

- Pass/Fail Criteria: If the specimen does not catch fire or explode, it is considered qualified.

Technical parameters:

| Drop Height | 300~1500mm (Controllable, steel ruler, min. indication value :1mm) |

| Testing Method | Face, edge, corner dropping |

| Test Loading | 0~5kg |

| Specimen Max. Dimension | W200 x D200 x H200mm |

| Drop floor material | A3steel plate (Acrylic plate, marble plate, wooden plate optional) |

| Drop floor dimension | W600 x D700 x H10mm(solid plate) |

| Machine weight | About 250kg |

| Machine dimension | W700 X D900 X H1800mm |

| Machine Power | 0.75KW |

| Drop method | Pneumatic dropping |

| Lifting method | Motor lifting |

| Power Source | 220V 60Hz |

| Safety Device | With 500MM height rail |

| Air Source | <1mpa |

| Control Method | PLC Touch Screen Control |