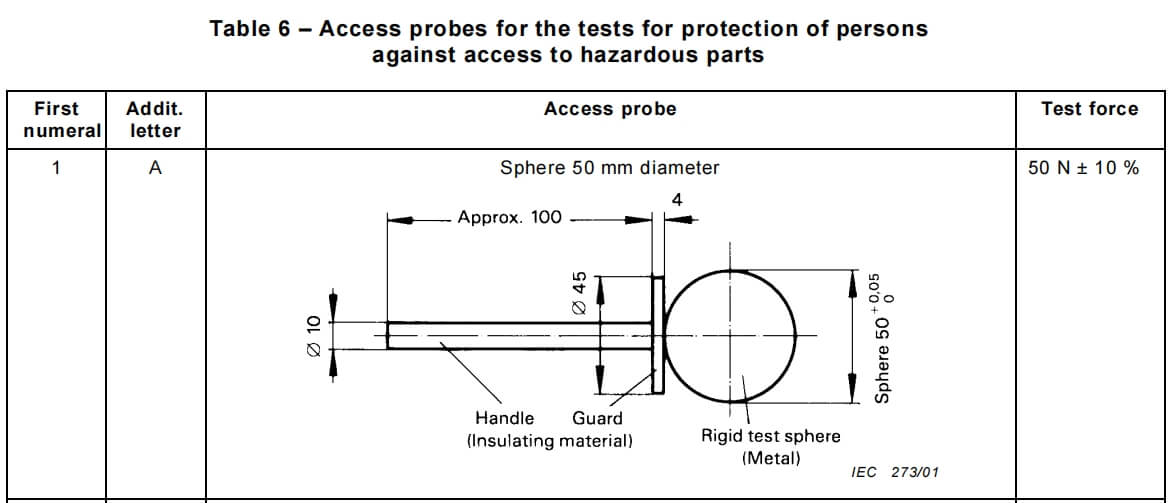

IEC 60529 50mm Sphere IP1X test probe A with 50N force

IP code probes are intended to verify

- the protection of persons against access to hazardous parts;

- the protection of the equipment against the ingress of solid foreign objects.

Probe and application:

- Access probes of IEC 60529 (IP code) to verify protection of persons against access to hazardous live parts or hazardous mechanical parts

- Probe code: A

- Figure No. :1

- Short description: Sphere: ∅ 50 mm with handle

- Force to be applied : 50N

This probe is intended to verify the protection of persons against access to hazardous parts. It

is also used to verify the protection against access with the back of the hand.

There are two kinds of IP1X test probe, one is without force, another is with 50N force.

Model:

BND-A( steel probe without force)

BND-AF(steel probe with 50N force)

Technical Parameters:

1. Ball Diameter: 50mm

2. Baffle Plate Diameter: 45mm

3. Baffle Plate Thickness: 4mm

4. Handle Diameter: 10mm

5. Handle Length: 100mm

6. Force: 10N/20N/30N/40N/50N

7. Standard: according to IEC 61032 figure 1 (the Test probe A), IEC 60529 table 6.

Pictures:

50mm steel ball /IP1X test probe A without force

50mm steel ball/ IP1X Test probe A with 50N

FAQ:

- What is IP1X Ingress Protection Testing?

IP1X testing is a type of ingress protection testing that measures the level of protection a product provides against solid foreign objects entering the product’s enclosure. The IP1X rating indicates that the product is protected against the entry of any object larger than 50mm in diameter.The IP1X testing process involves subjecting the product to a variety of tests to ensure that it meets the requirements for protection against solid foreign objects. - How is IP1X Testing Completed?

To test for IP1X, First, the enclosure is examined to ensure that there are no openings or gaps larger than 50mm in diameter that would allow solid objects to enter the enclosure. Then, the access probe is pushed against or inserted into any openings with 50N of force. - How Does IP1X Testing Help Manufacturers?

To test for IP1X, First, the enclosure is examined to ensure that there are no openings or gaps larger than 50mm in diameter that would allow solid objects to enter the enclosure. Then, the access probe is pushed against or inserted into any openings with 50N of force.If any openings larger than 50mm are found, the enclosure cannot be rated as IP1X.It’s worth noting that IP1X is a relatively low level of protection against solids and does not provide much protection against small objects or dust. Higher IP ratings are available for enclosures that require greater protection against solids or liquids. - How Does IP1X Testing Help Manufacturers?

IP1X testing, which evaluates the level of protection offered by an enclosure against the ingress of solid objects, can be helpful to manufacturers in several ways:

Compliance

IP1X testing is often required by regulatory bodies and standards organizations to ensure compliance with safety standards. By testing their products and demonstrating compliance with these standards, manufacturers can avoid costly fines and legal issues.

Quality Assurance

By subjecting their enclosures to IP1X testing, manufacturers can ensure that their products meet the level of protection they claim to provide. This helps to establish trust with customers and can lead to increased sales.

Design Improvement

IP1X testing can also help manufacturers identify weaknesses or design flaws in their enclosures, allowing them to make improvements and provide better protection to their customers. This can lead to higher quality products and a stronger reputation for the manufacturer.

Competitive Advantage.

By achieving a higher IP rating, such as IP1X, manufacturers can differentiate their products from competitors and offer a unique selling point to customers.