Industrial IPX9K High-Pressure Waterproof Testing Equipment – BONAD Open-Type IPX9K Test Chamber

The open-type design allows flexible testing of large or irregular samples, while advanced features such as an adjustable turntable, high-temperature water pumps, precise flow and pressure control, and a user-friendly touchscreen control system provide reliable, repeatable, and standard-compliant IPX9K testing. This makes the chamber ideal for R&D, quality inspection, design validation, and factory acceptance testing across automotive, electronics, and aerospace industries.

IPX9K Waterproof Test Chamber Test Principle

The IPX9K test verifies a product’s ability to withstand intense water jets from four defined angles under controlled pressure, temperature, and flow rate.

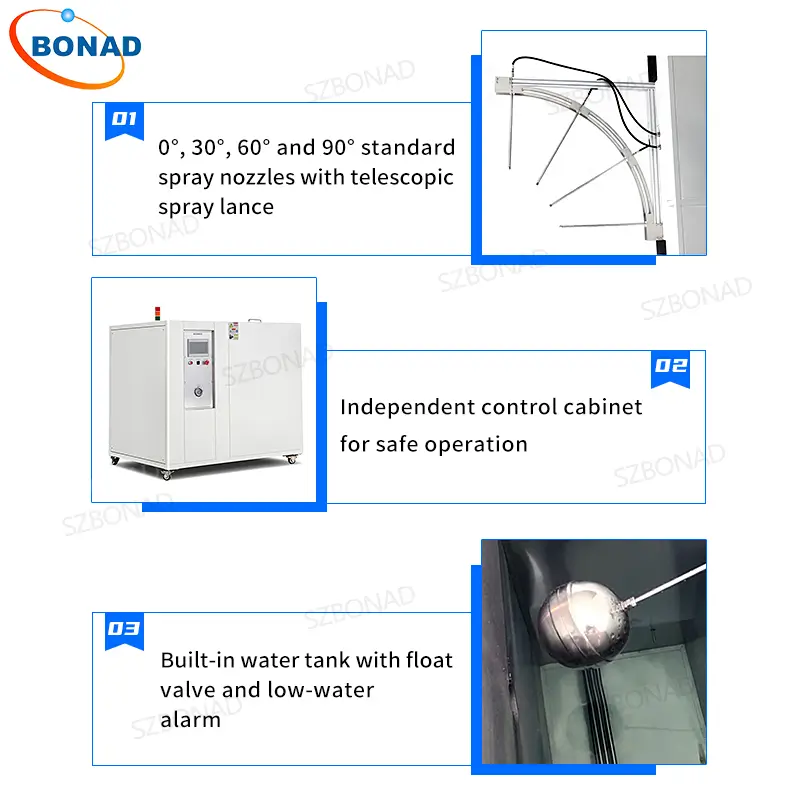

- Four fan-shaped nozzles positioned at 0°, 30°, 60°, and 90°.

- High-pressure hot water jets impact the sample surface.

- The test sample rotates continuously to ensure uniform exposure.

- Performance is evaluated after testing to determine ingress protection compliance.

Applicable Standards

The Open-Type IPX9K Waterproof Test Chamber is designed and manufactured in accordance with the following international standards:

- IEC 60529 – Degrees of Protection (IP Code).

- IEC 60068-2-68 – Environmental testing.

- ISO 20653 – Road vehicles — Degrees of protection (IP code).

- DIN 40050-9 – IP protection for road vehicles (IPX9K).

Typical Applications

- Passenger cars, buses, trucks, motorcycles.

- Automotive lamps, sensors, ECUs, connectors.

- Electric vehicle components and battery housings.

- Industrial electrical enclosures.

- Aerospace and rail transit components.

- Outdoor electronic devices and control boxes.

It supports R&D validation, design improvement, quality inspection, and factory acceptance testing.

Key Features

- Designed specifically for IPX9K waterproof testing.

- Open-type structure for large, heavy, or non-standard samples.

- Entire structure, chamber, and turntable made of SUS304 stainless steel.

- Four vertically arranged fan-shaped nozzles manufactured strictly to standard requirements.

- Hot water temperature adjustable via touchscreen.

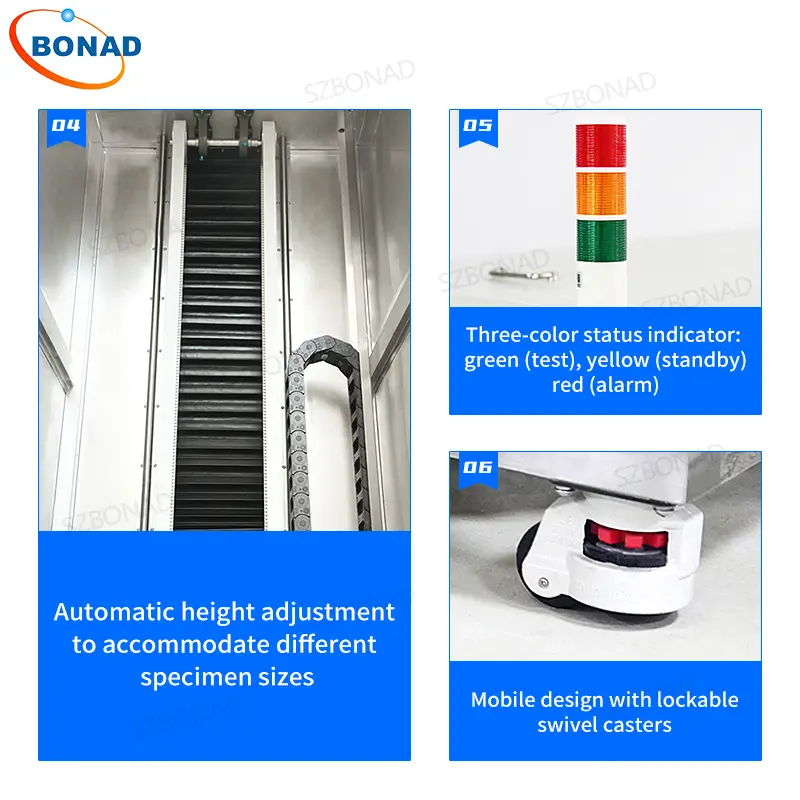

- High-precision stepper motor driven turntable, speed and angle fully adjustable.

- High-temperature, high-pressure water pump for long-term stable operation.

- Test duration programmable from 0–999 minutes.

- Advanced control system with 7-inch MCGS touchscreen + Panasonic PLC.

- Electrical components from internationally recognized brands (LS, Omron, Panasonic).

- Customizable configuration according to specific test requirements.

Technical Specifications

| Category | Specification |

|---|---|

| Spray Pressure | 8,000–10,000 kPa |

| Water Temperature | Ambient to 85°C (adjustable) |

| Nozzle Quantity | 4 |

| Nozzle Angles | 0°, 30°, 60°, 90° (vertical) |

| Flow Rate per Nozzle | 14–16 L/min |

| Water Impact Force | 0.9–1.2 N |

| Spray Arc Radius | 800 mm |

| Adjustable Nozzle Distance | 350 mm |

| Turntable Diameter | 800 mm |

| Turntable Load Capacity | 100 kg |

| Turntable Speed | 4–10 r/min (adjustable) |

| Turntable Height Adjustment | 700–1700 mm |

| Water Tank Capacity | 500 L |

| Water Tank Material | Stainless Steel (SUS304) |

| Insulation Thickness | 80 mm |

| Pump Type | Italian HAWK High-Pressure Pump |

| Water Supply System | 4 independent nozzle circuits, solenoid valve control, filtration system |

| Electrical Supply | AC 380V ±10%, 50Hz ±10%, 3-phase, 4-wire + PE |

| Control System | 7-inch MCGS Touchscreen + Panasonic PLC |

| Sample Power Modes | ON / OFF / Power Cycling |

| Test Duration | 0–999 minutes (programmable) |

| Safety Protection | Leakage, overload, short-circuit |

BONAD Open-Type IPX9K Waterproof Test Chamber – Stainless Steel Structure

Full stainless steel structure without coating, ensuring corrosion resistance and long-term durability.

IPX9K Water Supply System

- Intelligent constant-flow control using high-precision flowmeter and DA module.

- Real-time flow monitoring with inverter-controlled pump speed.

- Four independent water supply circuits for each nozzle angle.

- High-pressure flexible hoses with solenoid valve control.

- Built-in water quality filter at pump inlet

Control System

- IPX9K high-pressure spray control.

- Automatic constant-flow regulation.

- Programmable test time control.

- 7-inch full-color touchscreen interface.

- Sample power modes:

- Power ON.

- Power OFF.

- Power cycling.

- Controller: Panasonic PLC (Japan).

- Stepper motor driver: JMC.

- Imported electrical components (LS, Panasonic, Omron, etc.).

- Safety protections:

- Leakage protection.

- Overload protection.

- Short-circuit protection.

Why Choose This Open-Type IPX9K Waterproof Test Chamber?

- Strict compliance with global IPX9K standards.

- Reliable performance under extreme temperature and pressure.

- Industrial-grade components for long service life.

- Flexible open-type design for complex testing needs.

- Ideal for manufacturers, laboratories, and certification bodies.

Design & Construction Details

FAQ

1. What is the Open-Type IPX9K Waterproof Test Chamber?

The Open-Type IPX9K Waterproof Test Chamber is a high-performance testing system designed to evaluate products under high-pressure, high-temperature water jets. Its open-type structure accommodates large or irregular samples, making it ideal for automotive, electronics, and aerospace applications.

2. What is the difference between IPX9 and IPX9K?

- IPX9: Used for general industrial products, test pressure around 80–100 bar, water at room temperature or slightly elevated.

- IPX9K: Designed for automotive and transportation industries, same pressure but high-temperature water up to 80°C, simulating harsh cleaning and operational conditions. In short, IPX9K is an upgraded version of IPX9 emphasizing high-temperature, high-pressure testing.

3. Why are IPX9/9K tests considered the highest-level waterproof tests?

IPX9/9K represents the highest protection in international standards because it requires products to withstand:

- High-pressure water jets (8,000–10,000 kPa).

- High-temperature water (up to 80°C).

- Multi-angle spraying (0°, 30°, 60°, 90°).

- Continuous rotation exposure. This ensures products remain waterproof under extreme conditions, far beyond IPX1–IPX8 levels.

4. Why is high-temperature water required for IPX9/9K testing?

- High-temperature water simulates steam cleaning and high-temperature industrial conditions.

- Hot water increases penetration, strictly testing sealing performance.

- Ensures testing results reflect real-world durability under extreme conditions.

5. Can the chamber handle continuous testing for long durations?

Yes, the chamber is designed for long-term operation, with a high-performance Italian HAWK pump and heat-resistant components, allowing continuous testing without performance degradation.

6. Is it possible to adjust the water temperature precisely during a test?

Absolutely. The system features an adjustable heating unit controlled via touchscreen, allowing precise water temperature control from ambient up to 85°C.

7. What safety features are included for operators?

The chamber includes leakage protection, overcurrent and short-circuit safeguards, emergency stop functions, and insulated high-temperature water circuits, ensuring safe operation during all test scenarios.

8. Can the system store and recall previous test settings?

Yes, the touchscreen control system allows users to save and recall multiple test programs, simplifying repeated testing for similar products.

9. What support is available after purchase?

The manufacturer provides installation guidance, operational training, spare parts, and technical support, ensuring smooth commissioning and long-term reliable operation.

10. What are the maintenance requirements?

- Regularly check water tank and pump cleanliness.

- Ensure nozzles are free of blockage.

- Inspect electrical system and safety protections.

- Calibrate flow and pressure sensors periodically.